Heating Press Equipment

Both finger joining method (fusion joint) and skived joining method (glued joint) at the end requires heating to complete the bonding procedure of the joint in general. Heating press equipment provides heat energy, pressure required as well as belt ends fixture for the completion of the joining process.

Depending on the belt types and joining method, single-sided heating press or double-sided heating press is adopted.

- Single-sided heating press: Belt joint is heated on lower face only

- Double-sided heating press: Belt joint is heated on both upper and lower faces

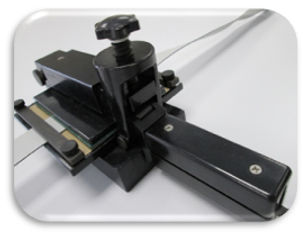

Single-sided heating press

-

Heating by lower plate only.

-

Mostly specified in skived/glued joining method at fixed temperature (115℃, max130℃).

-

Adjustable toggle latch to lock the upper plate and exert pressure on the joint.

Click the link below for more details

Double-sided heating press

-

Heating by both upper and lower plate.

-

Upper and lower plate can be set individual heating temperatures.

-

Heating temperatures and timer can all be set on one compact control box.

-

Natural cooling or water cooling available.

-

(Small press by natural cooling)

Click the link below for more details

The above small and portable presses are convenient for on-site joining or small volume in-house purpose. For the joining works of conveyor belts or power transmission belts in volume production, you may require more efficient press to increase the productivity. Our HPDW series could be your best choice.

Features:

- Double-sided heating plates

- Length of the effective press range: 300 mm, 800 mm, 1,200 mm and above.

- Water cooling to shorten the joining cycle.

For more info, please contact us via email: info@movemax.com.hk